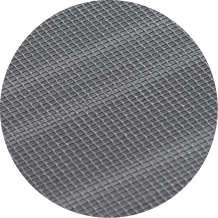

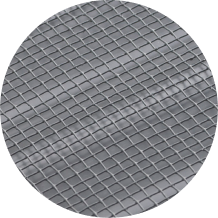

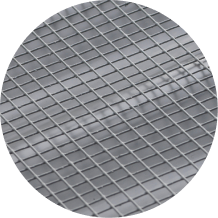

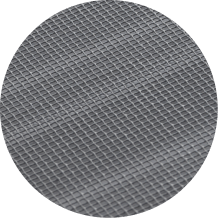

5.4mm Steel

Keeps out large leaves

Keeps out pests and vermin

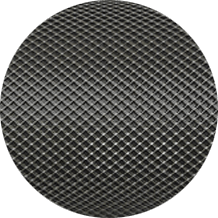

Bushfire compliant

High strength

Withstands hail & snow

Benefits

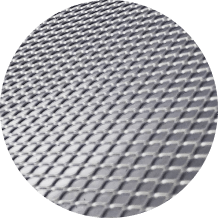

Get superior strength and durability

Benefits

Keep out large leaves and pests

Benefits

Install with ease on any roof

Benefits

Benefits of 5.4mm Steel

The strength of steel ensures a strong barrier against pests and vermin attempting to enter your roof cavity, preventing wild animals from making your home their home.

Blue Mountain Co 5.4mm Steel Gutter Mesh is a bushfire compliant mesh, meaning it is a safe, non-combustible material that can be used in bushfire zones as gutter guard. Note: Only “ember guard compliant” mesh will keep both leaves and embers out of your gutters, providing maximum defence against ember attack. That’s why we recommend our 2mm steel gutter mesh for all homes in requiring protection against embers.

Hail and snow are somewhat unpredictable forces of nature, but if you live in an area that has experienced them before, we would recommend a steel gutter mesh which is strong enough to withstand the weight and impact of hail.

Benefits

Get superior strength and durability

Benefits

Keep out large leaves and pests

Benefits

Install with ease on any roof

Benefits

Benefits of 5.4mm Steel

The strength of steel ensures a strong barrier against pests and vermin attempting to enter your roof cavity, preventing wild animals from making your home their home.

Blue Mountain Co 5.4mm Steel Gutter Mesh is a bushfire compliant mesh, meaning it is a safe, non-combustible material that can be used in bushfire zones as gutter guard. Note: Only “ember guard compliant” mesh will keep both leaves and embers out of your gutters, providing maximum defence against ember attack. That’s why we recommend our 2mm steel gutter mesh for all homes in requiring protection against embers.

Hail and snow are somewhat unpredictable forces of nature, but if you live in an area that has experienced them before, we would recommend a steel gutter mesh which is strong enough to withstand the weight and impact of hail.

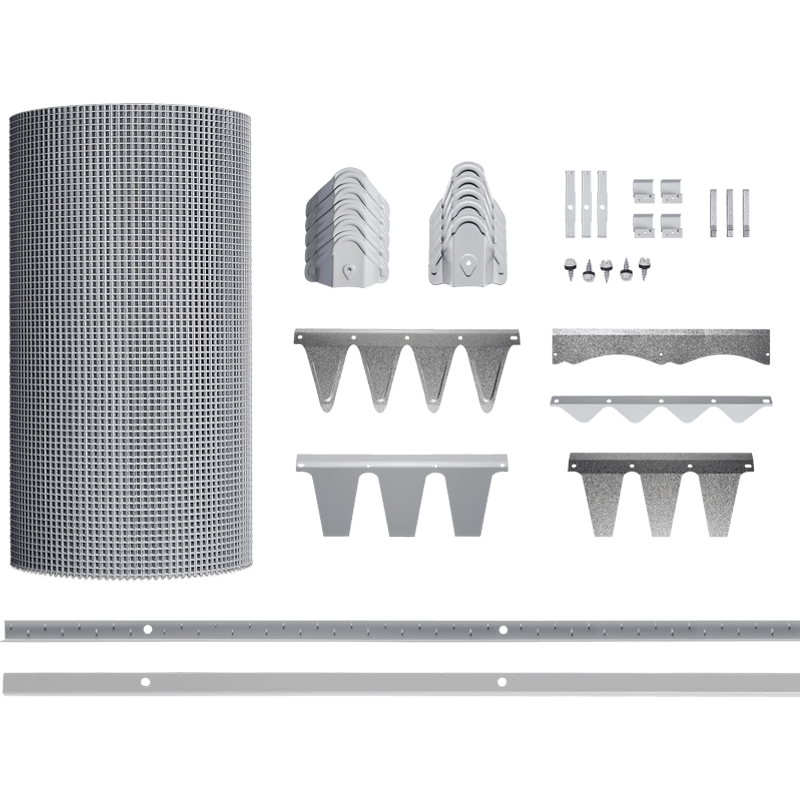

Pick your kit

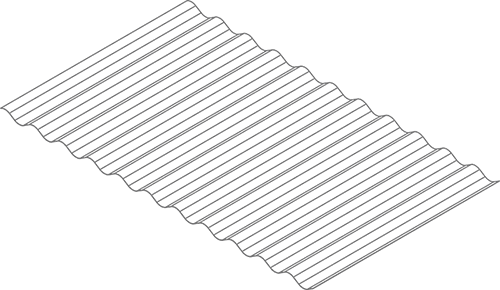

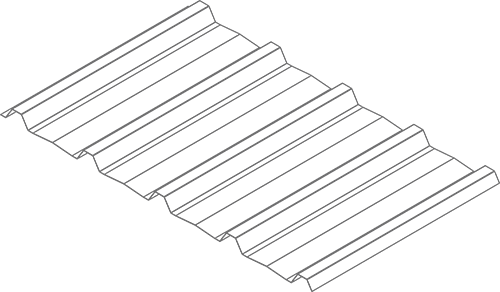

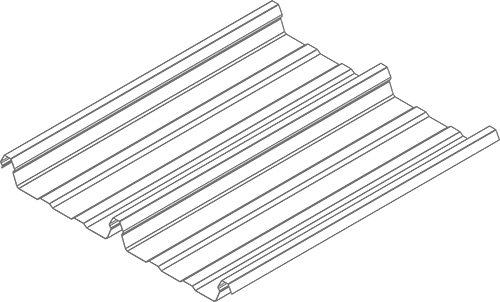

Select your roof type:

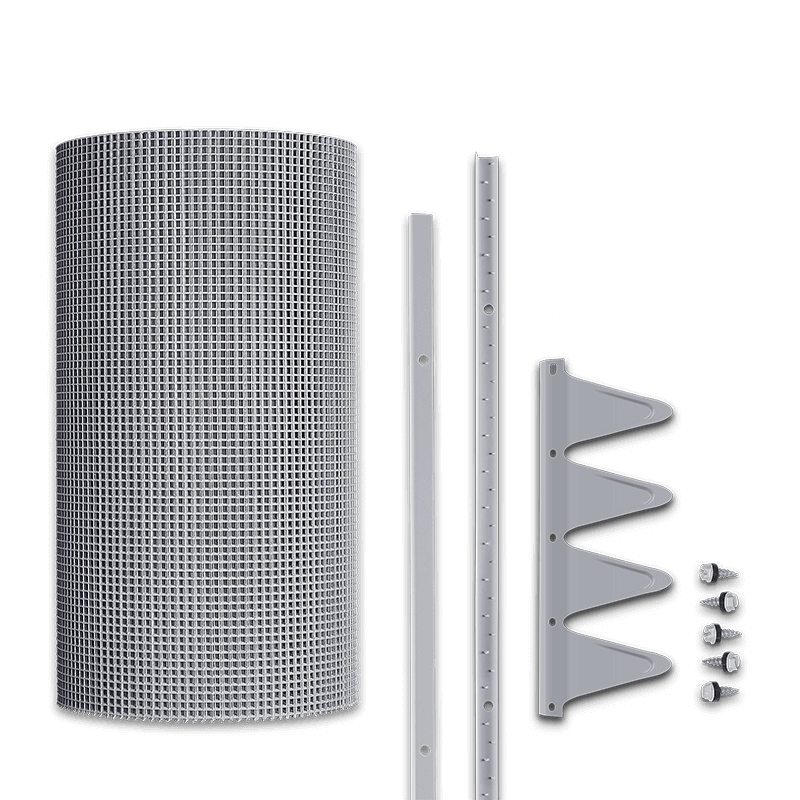

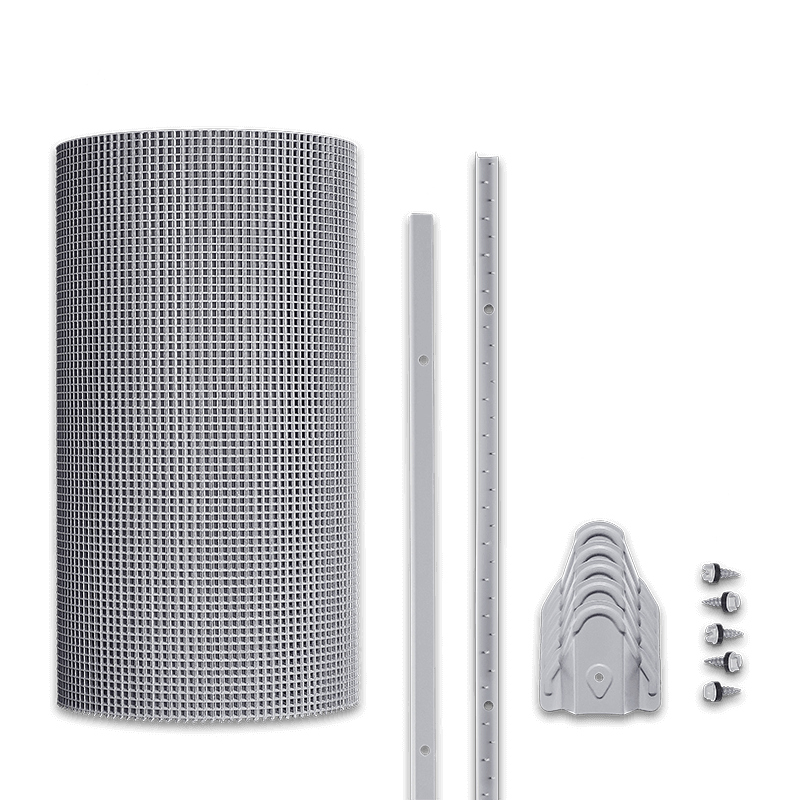

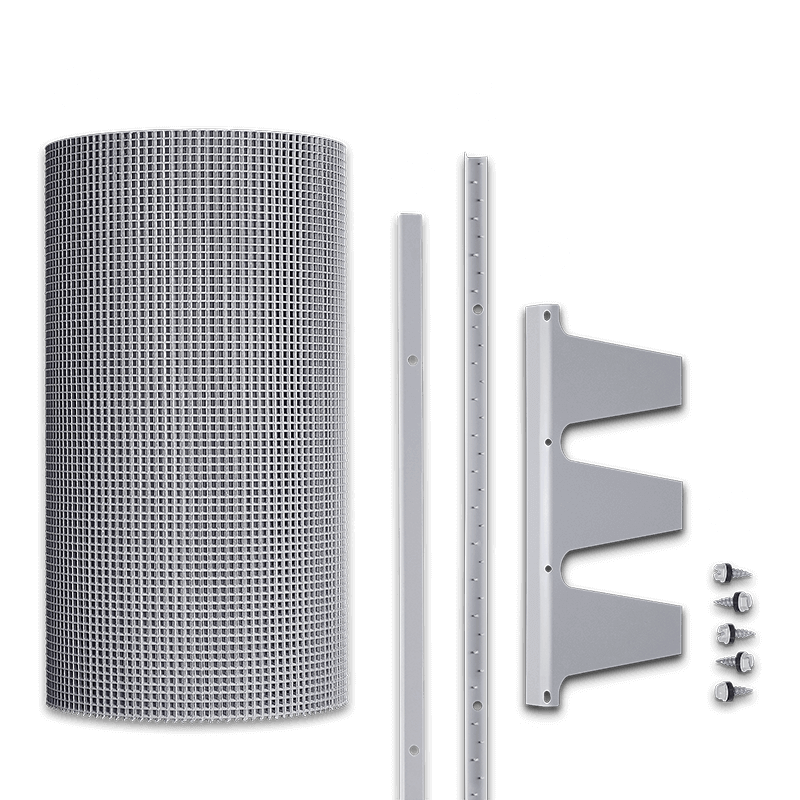

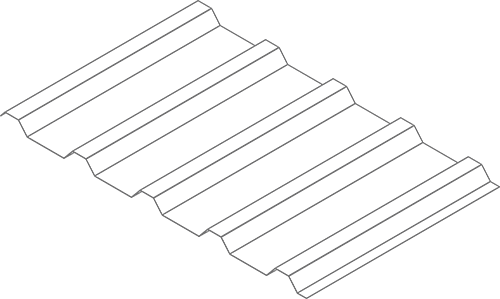

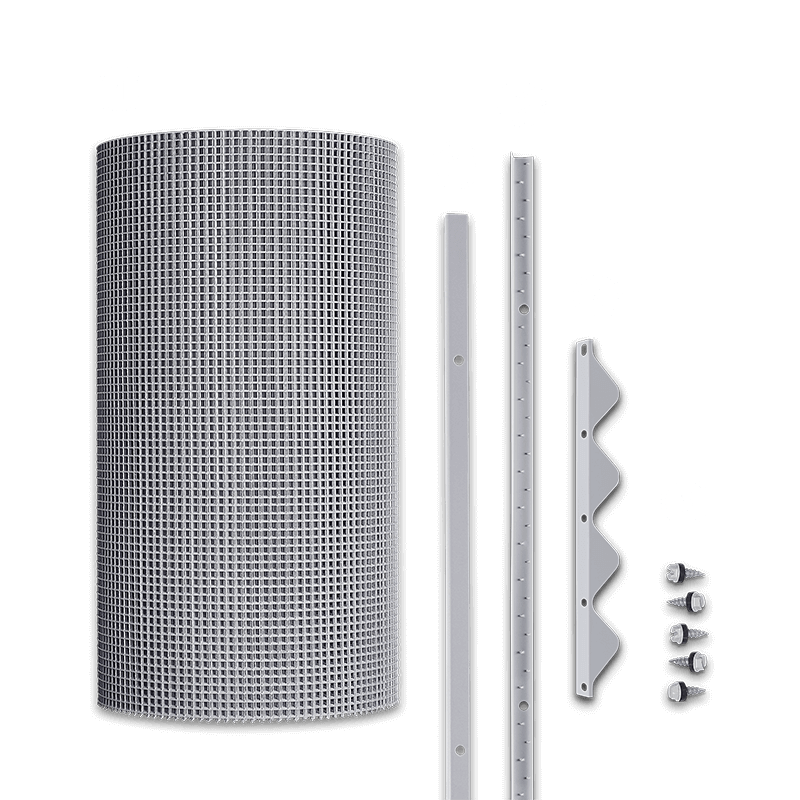

Your Corrugated roof kit includes

1. Mesh roll,

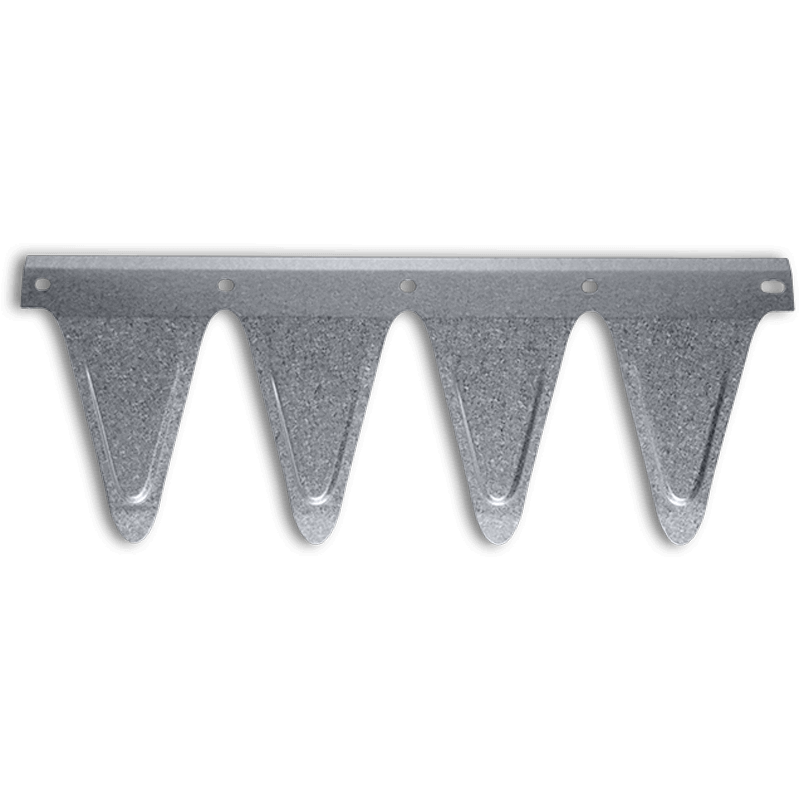

2. Standard Gutter Trim,

3. Mesh Lock Gutter Trim (optional upgrade – not included in standard kits),

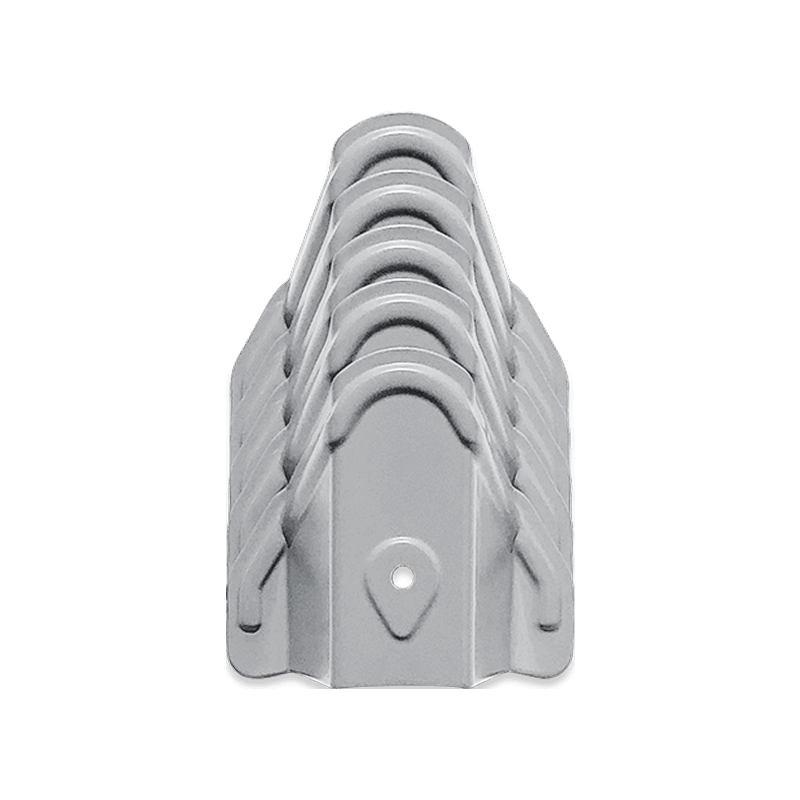

4. Corrugated Profile,

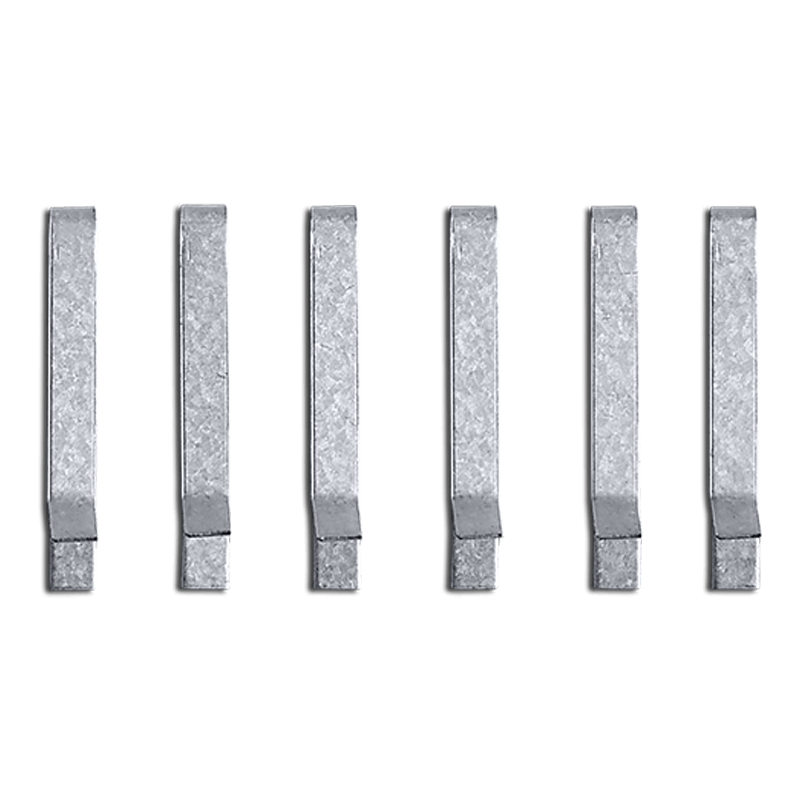

5. Metal Screws

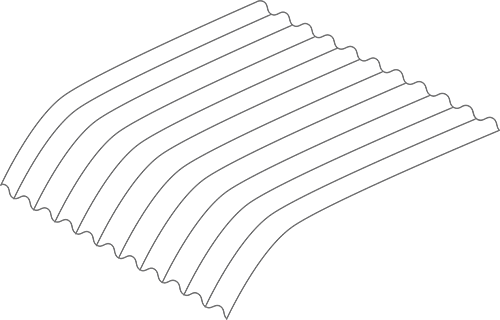

Roof information

- Lysaght Custom Orb

- Fielders S rib

- Metroll Corodek

- Revolution Corrugated

- Stramit Corrugated

- Stratco CGI 16mm®

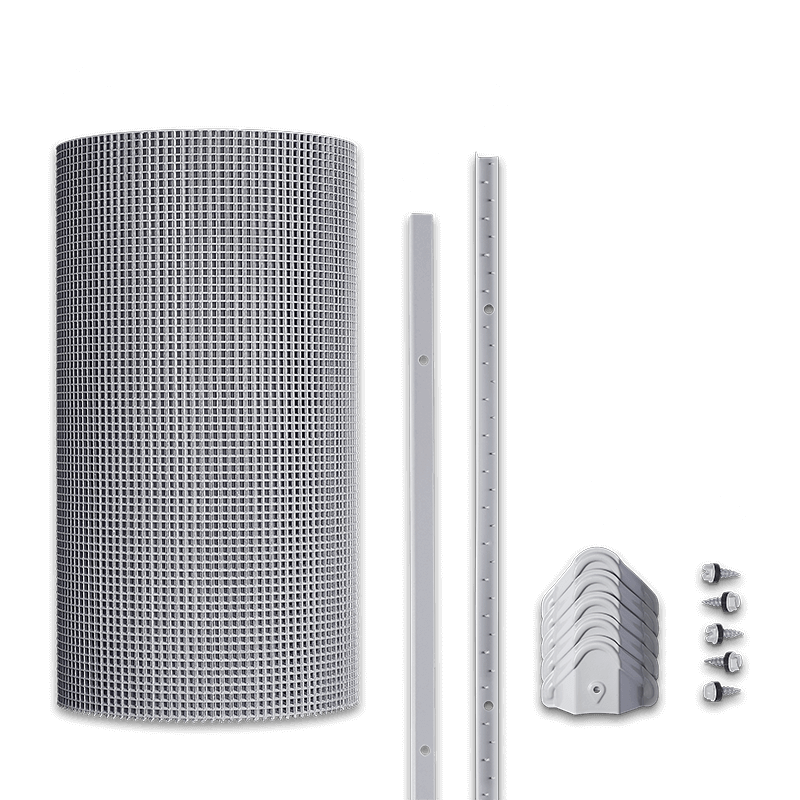

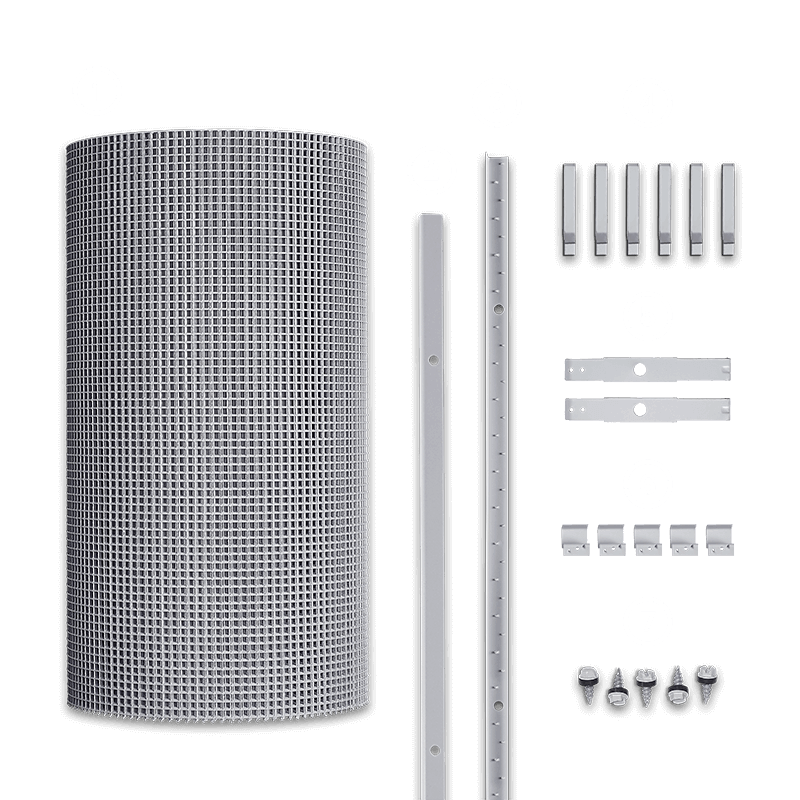

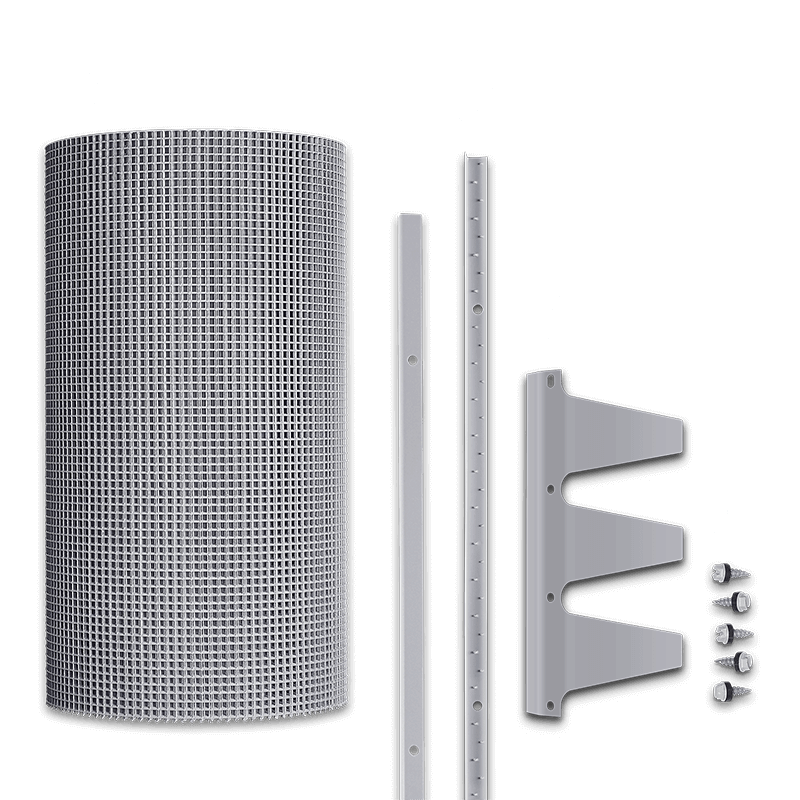

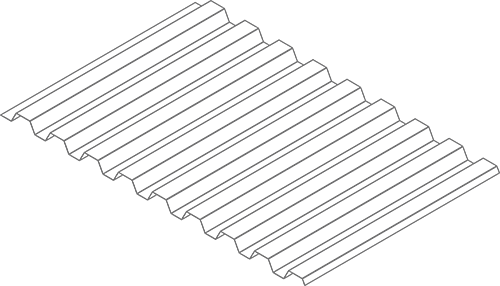

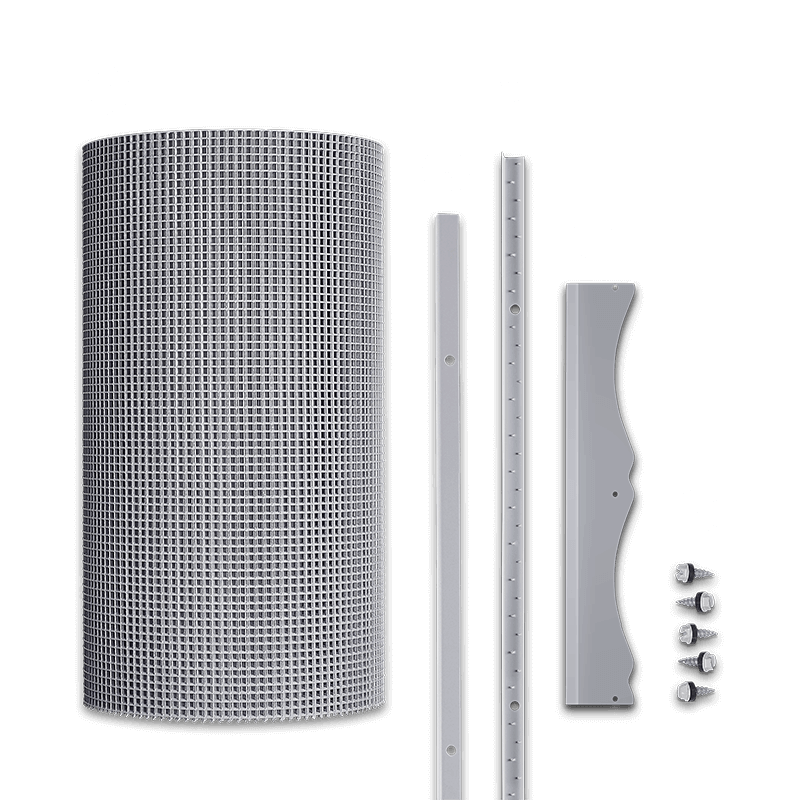

Your Trimdek® roof kit includes

1. Mesh roll,

2. Standard Gutter Trim,

3. Mesh Lock Gutter Trim (optional upgrade – not included in standard kits),

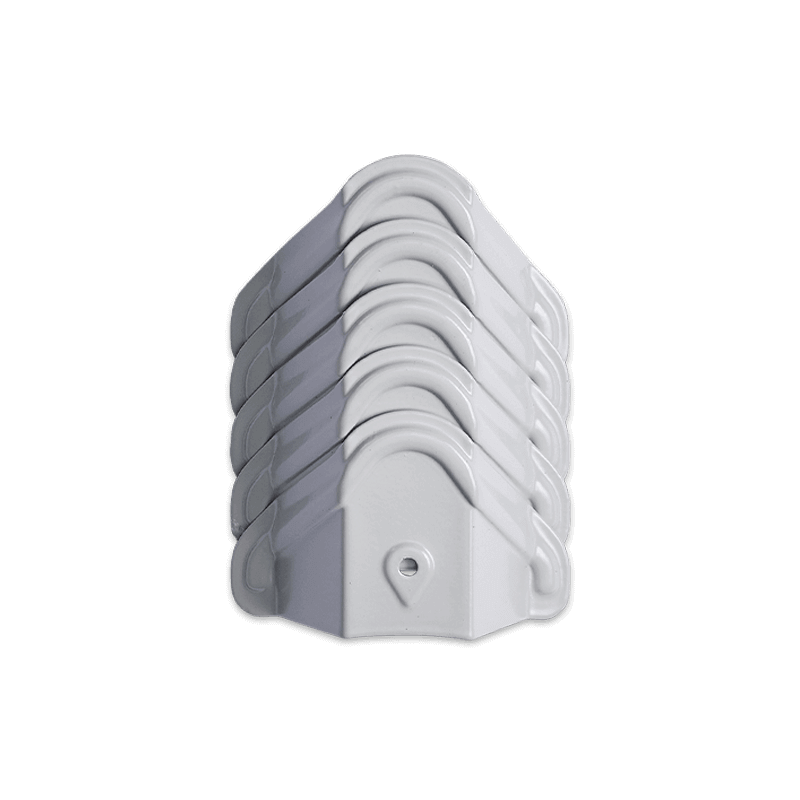

4. Trimdek® Saddles,

5. Metal Screws

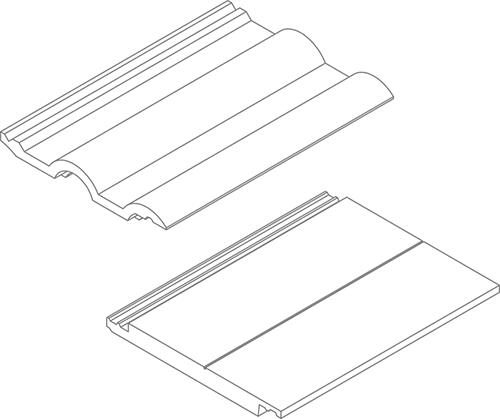

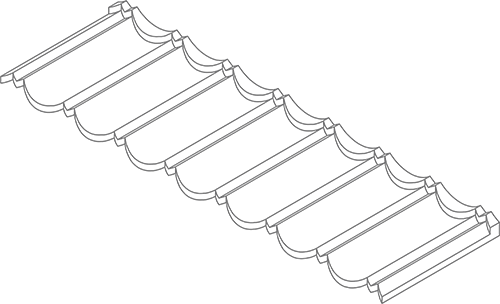

Roof information

- Lysaght Trimdek

- Stramit Monoclad

- Stratco Supderdek®

Your Klip-Lok® roof kit includes

1. Mesh roll,

2. Standard Gutter Trim,

3. Mesh Lock Gutter Trim (optional upgrade – not included in standard kits),

4. Klip-Lok® Saddles (optional),

5. Metal Screws

Roof information

- Lysaght Klip-Lok 406

- Lysaght Klip-Lok Classic

- Lysaght Klip-Lok Hi Strength

- Fielders KingKlip

- Metroll Metlok

- Revolution Revklip

- Stramit Speed Deck Ultra

- Stratco Topdek 700

Your Tile roof kit includes

1. Mesh roll,

2. Standard Gutter Trim,

3. Mesh Lock Gutter Trim (optional upgrade – not included in standard kits),

4. Standard Tile Clips,

5. Z-clips (optional),

6. Safety Clips,

7. Metal Screws

Roof information

Your Longspan® roof kit includes

1. Mesh roll,

2. Standard Gutter Trim,

3. Mesh Lock Gutter Trim (optional upgrade – not included in standard kits),

4. Longspan® Profile,

5. Metal Screws

Roof information

- Stramit Longspan

Your Spandek® roof kit includes

1. Mesh roll,

2. Standard Gutter Trim,

3. Mesh Lock Gutter Trim (optional upgrade – not included in standard kits),

4. Spandek® Profile,

5. Metal Screws

Roof information

- Lysaght Spandek

- Metroll Metrospan

Your Bullnose roof kit includes

1. Mesh roll,

2. Standard Gutter Trim,

3. Mesh Lock Gutter Trim (optional upgrade – not included in standard kits),

4. Bullnose Profile,

5. Metal Screws

Roof information

- Lysaght Custom Orb

- Fielders S rib

- Metroll Corodek

- Revolution Corrugated

- Stramit Corrugated

Your Decramastic roof kit includes

1. Mesh roll,

2. Standard Gutter Trim,

3. Mesh Lock Gutter Trim (optional upgrade – not included in standard kits),

4. Decramastic Profile,

5. Metal Screws

Roof information

Available in an extensive range of COLORBOND® swatches

Blue Mountain Co gutter mesh and componentry come in an extensive range of COLORBOND® colours to suit a wide range of properties.

Available in an extensive range of COLORBOND® colours.

Blue Mountain Co Gutter Mesh and componentry come in an extensive range of COLORBOND® and tile colours to suit a wide range of properties.

Compare with other mesh kits

Installation & Maintenance

Document Name

You may also like

Find the right mesh for you

For Architects and Building Professionals,

Download the Commercial version of the Handbook here